+44 208 391 0121

Now, with better user experience

WOSP Hayabusa Starter Motor & Gear, 2kW

MRP Without VAT:£566.28

MRP With VAT:£679.54

985 in stock

Description

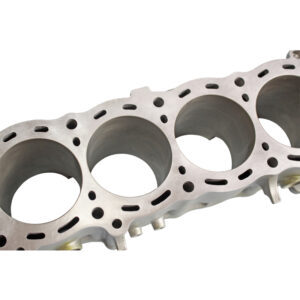

WOSP Hayabusa Starter Motor & Gear, 2kW

STR-BUSA-WOSP-01

SBD have spent a lot of time with WOSP developing a new starter motor for the Hayabusa. The new starter is 2Kw, which is then geared to give a constant speed as opposed to a high speed. This means that during cranking the trigger pattern is more constant. It has been re-geared it to increase the torque, this means that with long stroke engines the speed is considerably more consistent but much slower, something in the region of 400rpm, but when checked with an oscilloscope the consistency of the engine rpm when cranking is a huge improvement, even though the engine sounds slower when starting.

The shaft diameter of the starter has been increased and a new secondary gear, which is supplied with the starter motor to allow for this. The starter motor also has a clutch built into it, which has been especially designed so that if the vehicle does go backwards and engage the starter motor, it is designed to slip to help reduce the possibility of damage.

You will need our breather plate OS-DS-BUSA-BREATHER-01 or similar, because of the size of the starter motor.

Please make sure you have a sufficiently large enough battery, cranking amps of 450CCA (Lead acid type battery) or 670CCA (Litham type battery) is recommended and 35mm core cable. The distances must be as short as possible, ideally under 600mm.

Information about general bike starter motors

There are 2 main problems with bike engine starter motor designs; the first is that the bike manufacturer tries to produce a starter that is as light as possible and only just needs to get the engine started. However once the engine is tuned, most commonly in car applications, the compression is increased and so is the bore and stroke, this creates significant increases in loads on the starter motor system and as the engine reaches compression and then goes over the top of compression, the engine slows down and then speeds up dramatically. All ECUs have to work out from the trigger pattern as to its position and speed, so it knows when to fire the coils. This becomes an increasingly difficult problem. The standard starter motor does not produce enough torque and has a very small shaft that begins to distort as the loads increase on it, which makes the problem even worse. Many of the solutions have been to build a faster starter motor, the problem with this is that the speed during cranking is still erratic and when the trigger pattern is observed on the oscilloscope, the changes in speed during cranking are enormous, still causing starting issues.

The second issue is that if the driver spins the car and ends up going backwards, if the clutch is not dipped and the wheels start going backwards, the sprag clutch, which is like a rachet but allows the starter system to slip once the engine has started, will engage if the engine starts turning backwards. Quite often this will happen at high speed, which means the starter motor system is driven at much high rpm that it would have been when under normal starting and normally creates huge amount of damage because of this.

Related Products

Hayabusa Breather for Dry Sump Kit

SKU: OS-DS-BUSA-BREATHER-01MRP Without VAT:£70.20

MRP With VAT:£84.24

Heavy Duty Hayabusa Starter Clutch Kit

SKU: STR-BUSA-SPRAG-K-02MRP Without VAT:£317.95

MRP With VAT:£381.54

985 in stock