Dry Sump Tank 380mm tall, 165mm diameter

MRP Without VAT:£390.50

MRP With VAT:£468.60

992 in stock

Description

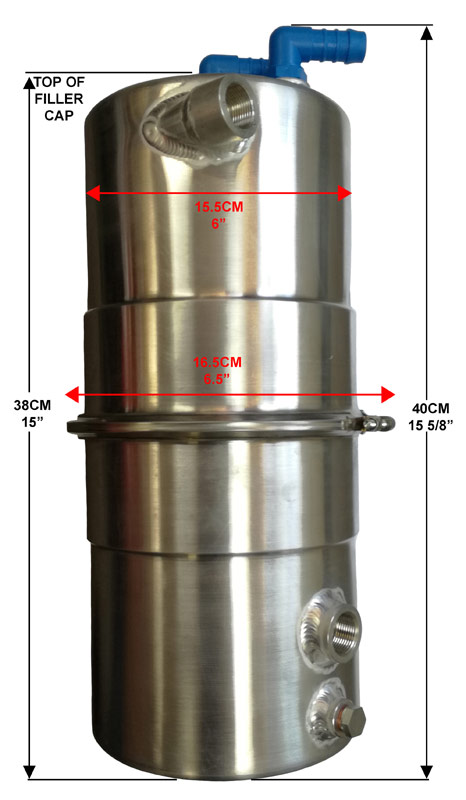

Dry Sump Tank, 380mm tall, 165mm diameter

OS-DS-TK-6.5-12

Dry sump tank 6.5″ (165mm) x 15″ (380mm), allow 15.75″ (400mm) for breathers, comes with -12 male ends.

Capacity – approx 5L.

No Base Plate.

Fully splitable washable tank with built in baffles.

Requires 2 x OS-DS-TK-C-M22-12JIC

This tank is specially produced for car that have a limited amount of height available and cannot fit our normal 5″ tank.

For use with any car engine.

On SBD dry systems, only the centre breather is used, the offset one is blanked off. Please be aware that non-SBD dry sump systems may have a different set up and you will have to contact the system manufacturer.

Due to the extremely clever design & complex baffle system, we designed this tank specifically to cope with the problems that can be associated with the Hayabusa engine, therefore we have designed it slightly differently to a normal dry sump tank. It has been made taller than normal and there is additional baffling to further improve air separation from the oil (please do not confuse this with other similar looking tanks). As far as using a circular tank is concerned, it is far more efficient for the returning air and oil mix to be spun around the wall of the round tank, so the air separates out and only oil can then reach the bottom of the tank.

Mounting Suggestion:

We have found the best way to mount all dry sump tanks is to either use or make some kind of cup for the base of the tank that has some kind of foam insulation or silicon and mount the cup to the chassis. Then sit the tank into it or make some simple brackets that locate the tank in 3 or 4 places around the edge of the base of the tank. These are again covered in a rubber or foam solution, then a foam pad fitted to the underside of the tank. We then use a large jubilee clip or something similar as high up as possible on the tank, which we cover with a heat shrink sleeving and then mount brackets onto the jubilee clip which are fitted to the chassis in one or two places.

Important Note:

Never to use forged 90-degree couplings. They create cavitation due to the fact that they prevent free flow, basically the problem is the coupling effectively has 2 opposing drills. This means that when the oil is fed at pressure instead of going through a smooth curve as it would with a swept coupling, the oil reaches the end of the drilling, some of the oil will pass around the corner and some will bounce back. We have seen engines fail by simply the addition of one forged coupling anywhere in the oil system, so we never recommend the use of this type of coupling because the only way to find out will be to see if your engine destroys itself.

Related Products

2.0L XE SBD Dry Sump Kit with 3-stage Pump

SKU: OS-DSK-VX2-US1MRP Without VAT:£2,265.00

MRP With VAT:£2,718.00

EcoBoost 1.6L Dry Sump Kit, Intake Side

SKU: OS-DSK-ECO1.6-01MRP Without VAT:£2,995.00

MRP With VAT:£3,594.00

SBD/Titan Duratec Twin Trough Dry Sump Kit, Inlet Side

SKU: OS-DSK-DURATEC-1-IN-AMRP Without VAT:£2,125.00

MRP With VAT:£2,550.00

Male/Male adapter M22x1.5 to -12JIC

SKU: OS-DS-TK-C-M22-12JICMRP Without VAT:£8.20

MRP With VAT:£9.84

992 in stock