Menu

- Home

- Cars

- Products

- Events

- Press

- News

- Technical Support

- DURATEC TECHNICAL SUPPORT

- Duratec Cooling Systems

- Duratec Crankshafts/Pistons/Con-rods

- Duratec Cylinder Head/Camshafts

- Duratec Electrical systems

- Duratec Engine Mount Kits

- Duratec Flywheel/Clutch Instructions

- Duratec Fuel Injection and SBD Throttle Body Kit

- Duratec Fuel System Instructions

- Duratec Oil Systems

- Duratec Rod Bolt Instructions

- Duratec Torque Settings

- ECOBOOST TECHNICAL SUPPORT

- EcoBoost Cambelt & Pulley Set Up

- EcoBoost Cooling Systems

- EcoBoost Crankshafts/Pistons/Con-rods

- EcoBoost Cylinder Head/Camshafts

- EcoBoost Direct Injection Fuel Systems

- EcoBoost Flywheel/Clutch Instructions

- EcoBoost Oil Systems

- EcoBoost Rod Bolt Instructions

- EcoBoost Torque Settings

- EcoBoost Turbo/Boost Control

- FUEL SYSTEM TECHNICAL SUPPORT & PRESSURES

- HAYABUSA TECHNICAL SUPPORT

- Hayabusa Cooling Systems

- Hayabusa Crankshafts/Pistons/Con-rods

- Hayabusa Cylinder Head/Camshafts

- Hayabusa Electrical systems

- Hayabusa Fuel Injection and SBD Throttle Body Kit

- Hayabusa Fuel System Instructions

- Hayabusa Gearbox & Clutch

- Hayabusa Oil Systems

- Hayabusa Torque Settings

- Hayabusa Wiring Instructions

- MBE ECUS & RELATED WIRING INFORMATION

- Helpful hints when starting your engine

- CAN Datastream

- EGAS/Fly-by-wire

- ECU Programming

- Gearbox Control & Components

- Launch Control & Components

- MBE9A4 ECU

- MBE9A4i ECU

- MBE9A6 ECU

- MBE9A8 ECU

- MBE9A9 ECU

- MBE9MD Display

- Older Unsupported Serial ECU Information

- Sensors

- Turbo/Boost Control

- Wiring Harness Instructions

- VAUXHALL TECHNICAL SUPPORT

- VX Cambelt & Pulley Set Up

- VX Cooling Systems

- VX Crankshafts/Pistons/Con-rods

- VX Cylinder Head/Camshafts

- VX Electrical systems

- VX Engine Mount Kits

- VX Flywheel/Clutch Instructions

- VX Fuel Injection and SBD Throttle Body Kit

- VX Fuel System Instructions

- VX Multi-throttle kits

- VX Oil Systems

- VX Rod Bolt Instructions

- VX Torque Settings

- DURATEC TECHNICAL SUPPORT

- FAQs

MBE9M4i ECU, Ignition Only up to 4-cylinders

MRP Without VAT:£394.00

MRP With VAT:£472.80

MBE9A4i ECU, Ignition Only up to 4-cylinders

985 in stock

Description

MBE9M4i ECU, Ignition Only up to 4-cylinders

MBE9M4I

This ECU is designed for ignition only control. It can run distributor or distributorless engines up to 4 cylinders; its possible inputs are crank speed & throttle angle. It can be used with ignition against speed or if a throttle position sensor is fitted to the carburettors, it can be programmed to change the ignition according to the open of the butterflies.

This is the new version which has superseded the MBE9A4i, all the pinouts and instruction sheets are the same as the 9A4i versions.

It uses USB communication from your laptop, which is then converted by a small piece of hardware (MBE985) that converts the USB in CAN, which is a more stable system, used by car manufacturers worldwide. You will need our basic CAN mapping kit MBE-MAP-KIT-3-CAN and the necessary adaptor, if you are using one of our harnesses, to read information and/or make changes to the mapping in the ECU.

All our MBE ECUs will be loaded with a base map as close as possible to your requirements. In addition they are capable of being adjusted by the user via a computer. All ECUs are fully tested during manufacture.

Crank Sensor & Trigger Wheel Input

Most manufacturers use inductive type crank sensors. If your engine uses the hall effect type, MBE ECUs can be built to order with this type of input.

MBE write special code to allow the use of a range of different trigger wheels, most commonly 60-2(GM/VW/Bosch), 36-1(Ford), 24-1(Suzuki Hayabusa) & 24-2(Suzuki Hayabusa 2008 & other late Japanese bike engines) to name but a few. The range of trigger wheel patterns is every increasing, so please download Easimap 6 PC Software to check what patterns are currently available. We can supply a range of specialist sensors & suitable trigger wheels for applications that currently have no trigger wheel.

A special piece of software has been written by MBE for Hayabusa and other bike engine set ups called soft start, this was produced due to known problem with the standard starter motors, that if the battery got a bit low sometimes the engine would kick back on starting and engage the starter clutch. This would, if you were lucky only damage the starter clutch itself, but if unlucky could break off part of the engine cases. Without going into too much detail, the ECU allows the engine to get up to speed during cranking before attempting to start the engine, if the engine does not reach sufficient speed it will not allow the engine to start, so damage cannot occur.

Throttle Position Sensor Input

Throttle position sensors are used to inform the ECU of how much load is being applied. We sell a range of throttle position kits to use with Weber & Dellorto carburettor kits.

Ignition & Coil Input

The MBE9M4i has four ignition drives, that can be fired either sequentially or in wasted spark mode, depending on requirements & set-up. The normal MBE9A4i has built in amplifiers so there is no need for expensive external units. You can use coil on plug, which is four individual coils (such as used on the Suzuki Hayabusa & Duratec engines) or wasted spark coil packs (commonly used on older GM, Peugeot and Ford engines). If your coils have amplifiers built in, such as the Honda K20 coil, the MBE ECU can be specially built to suit this type of coil.

Water Temperature Input

Water temperature can be used on the MBE9A4i, but because this unit is designed to be simple to use, it is not a compulsory input. The MBE water temperature input circuitry allows the use of 2 different types of sensor, either the MBE/Bosch/Nippon Denso/Lucas water temperature sensors (all use the same calibration) (WTS1)or Ford type which uses a completely different resistor value. This is selectable within the ECU.

Barometric Pressure & Boost (MAP) Input

The pressure inputs can be used to compensate for Barometric & Manifold pressure changes, but they are never used on a simple installation e.g. 4-cylinder carburettor ignition systems.

The boost/MAP pressure sensor compensates for changes in manifold pressure, most commonly used with turbo applications. The sensor input is 0 – 5V, it is fully calibratable by the end user. The ECU will normally comes with calibration either for the MBE/GM sensor (car engine) or standard Suzuki/Nippon Denso sensor (bike engine). The ECU can make changes to fuelling & ignition according to pressure.

The barometric pressure sensor compensates for atmospheric pressure changes due weather conditions & altitude. The sensor input is 0 – 5V, it is fully calibratable by the end user. The ECU will normally come with calibration either for the MBE/GM sensor (car engine) or standard Suzuki/Nippon Denso sensor (bike engine).

Power Shift

Power shift can be configured in various different options, it’s simplest form is a single cut time. With use of ‘complete on target gear’, this allows the ECU to vary the cut time to lengthen or shorten it depending on how long the gear change takes. This time can vary dramatically depending on conditions (requires gear position sensor input). Powershift now has the option to either cut the spark, retard the spark or a combination of the two depending user requirements. There is an option for ‘cut when pin low’, this normally for use with external devices. Also there are many safety features built in, such as, lock out timers & continuous assert to protect against power shift being triggered accidentally.

Tachometer Output

The MBE9M4i ECU produces a square wave 12V output, this is configurable from within the ECU for the number of pulses that occur on the tacho signal per engine cycle. This means it can be programmed to suit your own tachometer’s requirements. The tacho signal also has programmable duty cycle. If you intend on using our MBE9MD display or a dash such as an AIM that can be configured to receive the information over CAN, you would be able to use the tacho output from the MBE for a different function since it would be no longer required.

Shift light & Warning systems Output

The shift light output is configurable in several ways, it could be set-up as a simple shift light which is purely rpm dependent. If you add a low pressure switch or pressure sensor to the MBE, you can set-up a low oil pressure warning, which can also be rpm dependent. This can be configured to trigger an oil light or linked to the shift light, so one output can do 2 functions. We also have designed a bleeper system, which many competition drivers use & find more unmissable.

Radiator Fan Output

The MBE9M4i is fully programmable, not only can it be programmed to switch off & on at given temperatures but it can even be programmed to run on after the ignition is switched off for a given length of time or until a specified temperature is reached. If you are programming for specified temperature after engine off, you would need to run an electric water pump to ensure water circulation.

Launch & Traction Control Output

Launch control on the MBE9M4i can be configured to use up to 7 different launch maps. Each map can be set with the different launch rpm & can be externally selected by the user depending on track conditions.

The launch control is activated with a launch switch (fitted to the clutch pedal SWT-MICRO-SL-LL-SS (NC)) & button (NO) either mounted on the dash or steering wheel with a sequence as follows;

1. Depress the clutch (switch triggered only when fully pressed to the floor), which activates launch switch.

2. Then push steering wheel button, which arms launch.

3. Release steering wheel button, launch then becomes active.

4. Depress throttle by desired amount, which will bring the engine rpm to your pre-set launch limiter (according to selected setting).

5. Then release clutch, the ECU then progresses though the launch map maintaining the programmed rev limits, which you have set to increase over a longer or shorter period of time as desired.

Uses the same selector as Traction Control. If traction control is set up within the MBE9M4i, the launch control will then switch from launch to traction control automatically, please discuss settings and set up with your engine programmer.

Data Logging/Histograms Output

The MBE9M4i has an inbuilt memory that can record a series of histograms & engine hour clock for recording total engine run time. This will enable the engine builder or programmer to monitor engine life if any misuse of the engine has occurred, such as excessive engine temperature or over-revving.

It is also possible to log direct to your laptop from the ECU any information being transmitted by your ECU provided your laptop is connected.

The MBE9M4i has a user configurable CAN data stream, this can be set up to be used with many external data loggers & displays. You would need to contact your data-logger/display manufacturer for the correct protocols.

Data Logging/CAN data stream Output

The MBE9M4i has a user configurable CAN data stream, this can be set up to be used with many external data loggers & displays. You would need to contact your data-logger/display manufacturer for the correct protocols.

More functions are continuously added to the MBE9M4i, please download Easimap 6 for the latest updates.

Related Products

Basic CAN Mapping Kit for MBE CAN based ECUs

SKU: MBE-MAP-KIT-3-CANMRP Without VAT:£160.00

MRP With VAT:£192.00

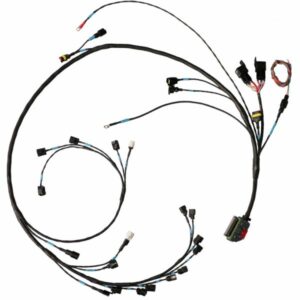

Ignition Only Wiring Harness for MBE9A4i ECU

SKU: LM9A4I-IC-WS-01MRP Without VAT:£155.37

MRP With VAT:£186.44

Micro Switch Sealed For Launch Control

SKU: SWT-MICRO-SL-LL-SSMRP Without VAT:£82.24

MRP With VAT:£98.69

Professional CAN Mapping Kit for MBE CAN ECUs

SKU: MBE-MAP-KIT-4-CANMRP Without VAT:£550.00

MRP With VAT:£660.00

Related products

Hayabusa Wiring Harness, use with MBE9A8 ECU

SKU: LM9A8-GSXR-M-OMSMRP Without VAT:£786.59

MRP With VAT:£943.91

Pneumatic Solenoid 3 Valve Kit, Cable Throttle

SKU: GEAR-PN-S-KIT-05-3MRP Without VAT:£665.15

MRP With VAT:£798.18

Pneumatic Solenoid 2 Valve Kit for EGAS system

SKU: GEAR-PN-S-KIT-05-2MRP Without VAT:£479.80

MRP With VAT:£575.76

Lamdba Wide Band Sensor 4.9 spec suit MBE9A9/9A6 ECUs

SKU: LMBDA-04MRP Without VAT:£125.00

MRP With VAT:£150.00

EGAS Motor Mount Kit to suit Gen 1 Hayabusa

SKU: EGAS-A-BUSA-01-KMRP Without VAT:£959.00

MRP With VAT:£1,150.80

985 in stock